No.16

15 June 2020

Kansai University Research: Cell membrane-inspired phospholipid polymers as new generation of biomaterials for medical devices

Yasuhiko Iwasaki

Professor, Faculty of Chemistry, Materials and Bioengineering

(Osaka, 15 June) Kansai University's Yasuhiko Iwasaki has developed innovative biocompatible phospholipid polymers for medical devices applications including biosensors for immunoassay platforms and robust, low-friction 'PEEK' based materials to replace metals in orthopedic implants.

Modern biosensors used as medical diagnostic devices are based on detecting antibody-antigen type reactions between proteins on micro-arrays patterned on solid substrates made of materials including plastics and semiconductors. Typically, functionalized active regions of the micro-arrays are fabricated using optical lithography used in semiconductor processing. However, there are two major difficulties in fabricating biosensing devices: The first is speed of the process and the second is related to preventing non-specific attachment of proteins to substrates. The speed and efficiency issue has be resolved by using 'photochemical fabrication'; a process that eliminates requirements for photomasks and patterns are produced directly onto substrates.

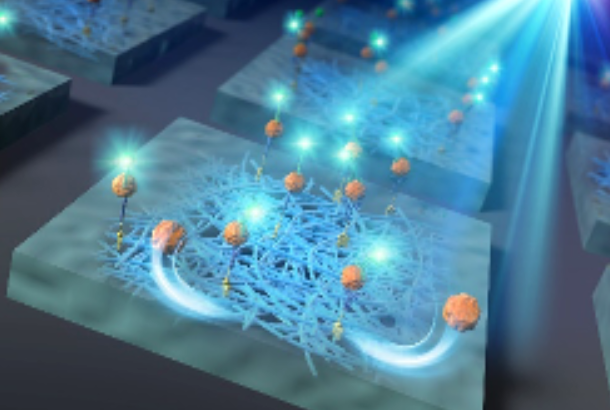

However, non-specific binding of proteins to substrates has been much more difficult to overcome because conventional substrates are not compatible with biomolecules, and it is extremely difficult to prevent non-specific attachment of proteins. With the aim of developing biocompatible substrates for diagnostic devices, a team led by Yasuhiko Iwasaki at Kansai University in Japan has patterned substrates using antifouling poly[2-methacryloyloxyethyl phosphorylcholine (MPC) polymers with residues of tyrosine. The researchers demonstrated that a combination of visible light assisted fabrication and the antifouling nature of PC polymers enabled them to control the immobilization of proteins onto specific regions of patterned arrays for applications in immunoassay platforms.

In their experiments Iwasaki and his colleagues immobilized proteins in so-called zwitterionic polymer networks to prevent denaturation of proteins if they interacted with substrates. Then a series of biochemical procedures were used to define micro-array patterns through TEM mesh masks that were irradiated with white light for 15 s. This process led to microarrays where nonspecific protein immobilization was eliminated on the nonirradiated regions of the surface.

"The immobilization process of proteins was easy, quick, safe, and reliable," says Iwasaki. "This result could serve as a basic design strategy for fabricating biosensors and diagnostic devices."

Video of the visible light irradiation process

Note: This video clip was provided by Royal Society of Chemistry.

(http://www.rsc.org/suppdata/d0/cc/d0cc02092c/d0cc02092c2.mp4)

Orthopedic medical applications of poly[2-methacryloyloxyethyl phosphorylcholine (MPC)

Iwasaki and his colleagues have also discovered that zwitterionic polymer brushes can be used for producing robust and low friction surfaces with potential medical applications including replacing metals in orthopedic implants.

Specifically, Iwasaki and his group used the photoreactive and water soluble zwitterionic monomer 2[2-(methacryloyloxy)ethyldimethylanmmonium] ethyl benzophenoxy phosphate (MBPP) to improve the stability of zwitterionic polymer brushes.

The researchers selected photosensitive poly(ether ether ketone) (PEEK) as a substrate and immersed it into aqueous solutions of 2-(methacryloyloxy)ethyl phosphorylcholine (MPC) and MBPP. The solution was then irradiated with UV light for 180 min. Optical and XPS measurements showed that this process created low friction-grafting layers of zwitterionic polymers on the PEEK samples.

"The bacterial adhesion was completely suppressed on the surface of PEEK modified with cross-linked PMPC brushes with MBPP," says Iwasaki. "Thus, we conclude that the surface modification of PEEK with MPC and MBPP can provide ideal surface properties for orthopedic devices.

References

Yasuhiko Iwasaki, Sukulya Bunuasunthonb and Voravee P. Hoven, Protein patterning with antifouling polymer gel platforms generated using visible light irradiation, Chem. Commun. 56, 5472, (2020).

Hiroki Nakano, Yuri Noguchi, Sachiro Kakinoki, Mai Yamakawa, Issey Osaka, and Yasuhiko Iwasaki, Highly Durable Lubricity of Photo-Cross-Linked Zwitterionic Polymer Brushes Supported by Poly(ether ether ketone) Substrate, ACS Appl. Bio Mater. 3, 1071, (2020).

Y. Iwasaki, A. Yokota, A. Otaka, N. Inoue, A. Yamaguchi , T. Yoshitomi , K. Yoshimoto , M. Neo, Bone-targeting poly(ethylene sodium phosphate), Biomater. Sci. 6:91-95, (2018).

Shunsuke Sugimoto and Yasuhiko Iwasaki, Surface Modification of Macrophages with Nucleic Acid Aptamers for Enhancing the Immune Response against Tumor Cells, Bioconjugate Chem. 29, 4160, (2018).

Graphic illustration of the visible light fabrication of protein patterns using antifouling polymer gel platforms. Cover of ChemComm 56 Number 4, 1 21 May 2020.

General information

Kansai University

3-3-35 Yamate-cho, Suita-shi,

Osaka 564-8680 JAPAN

EMAIL: kansai-u1886@ml.kandai.jp

Websites

Kansai University

http://www.kansai-u.ac.jp/English/

Kansai University e-bulletin

http://www.kansai-u.ac.jp/Kokusai/e-bulletin/